?

?

The crushing stage of iron ore processing aims to reduce the ore to the smallest possible particle size, significantly alleviating the load on subsequent grinding operations. This approach reduces overall energy consumption and costs, representing a key principle in modern mineral processing.

Crushing Process

]]>

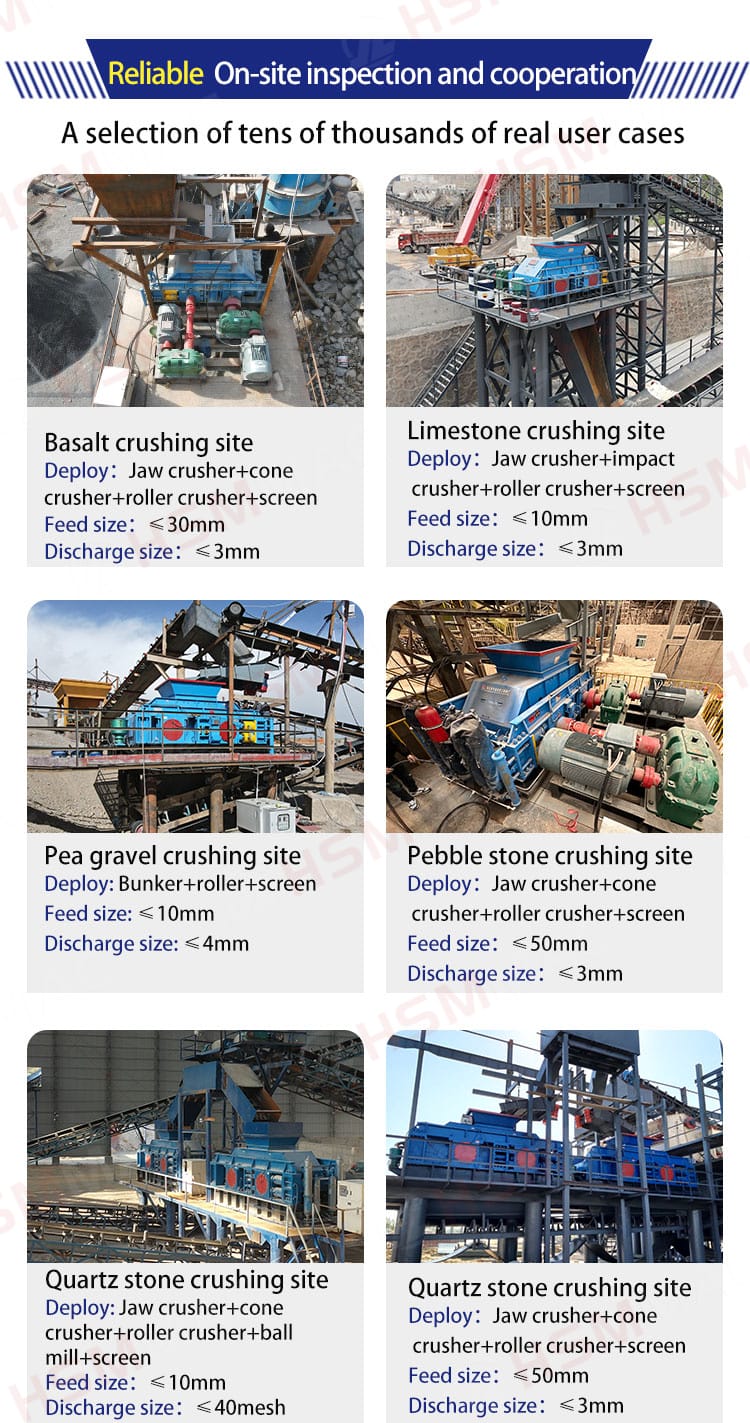

The customer employs three jaw crushers + one 1510 double-roll crusher + one 1080 double-roll crusher to process granite into sand. The jaw crushers serve as primary and secondary crushers, producing 1cm-sized output. The double-roll crusher accepts feed material under 5cm in size, with the finished sand product measuring under 3mm.

]]>

This case study depicts a client site in China for a limestone sand production line. The client required limestone to be crushed into sand, with the crushing process divided into three stages: The primary stage employs a jaw crusher to reduce large limestone blocks to 10cm fragments. These then proceed to the secondary stage, a cone crusher, for intermediate crushing, producing output of 2-3cm. Finally, the tertiary stage utilises a double-roll crusher to produce finished sand with an output size of 3mm.

]]>This is our Tanzanian client’s on-site gold processing project with a capacity of 3-5 tons per hour. The production line consists of three sections: a feed hopper + primary crusher (jaw crusher), which first crushes raw material measuring 20cm to 20-30mm. The secondary crusher (double-roll crusher) then reduces the 20-30mm material from the primary crusher to 0-5mm. Finally, the ball mill grinds the 0-5mm material through a buffer bin to 200 mesh, meeting our gold extraction requirements.

Gold Ore Crushing Production Line Recommendations

In the mineral processing industry, double-roll crushers or high-pressure roller mills are employed for fine crushing operations. Positioned upstream of ball mills, they can reduce 2-3 cm ore particles to less than 1 mm, significantly enhancing the operational efficiency of mineral processing ball mills and boosting overall production productivity.

]]>Loading video of roller crusher

The roller crusher primarily crushes materials through the compression and shearing action of two relatively rotating rollers. Materials enter the gap between the rollers and are crushed through compression and shearing. It is suitable for crushing fluorite and offers convenient particle size adjustment, enabling control over the size of the discharged material. However, there are issues related to production output. The processing capacity of the roller crusher is relatively moderate. For large-scale production, multiple units or larger models may be required.

]]>

The molybdenum ore beneficiation process includes several key stages that ensure efficient mineral recovery and high-grade concentrates. Here’s an overview:

1. Crushing and Screening

Molybdenum ore is first crushed using jaw crushers or double roller crushers to reduce large chunks into smaller, manageable sizes.

Vibrating screens remove oversized particles, ensuring uniform material for grinding.

2. Grinding and Classification

Crushed ore is sent to ball mills for fine grinding, turning it into fine powder.

Spiral classifiers or hydrocyclones then classify the ground material, separating fine particles for the next step.

3. Flotation

Flotation is the core process for molybdenum ore beneficiation. By adding flotation reagents, molybdenum minerals separate from impurities.

Froth containing molybdenum rises to the surface, forming the concentrate, while tailings are discharged.

4. Concentration and Filtration

The flotation concentrate undergoes thickening to remove excess water using a thickener.

Further dehydration is achieved with a filter press, resulting in low-moisture molybdenum concentrate.

5. Drying and Packaging

The filtered concentrate is dried in a rotary dryer.

Finally, the dry molybdenum concentrate is packaged and prepared for shipment or market use.

Recommended Equipment

Crushing: Double Roller Crushers, Jaw Crushers

Grinding: Ball Mills

Classification: Spiral Classifiers, Hydrocyclones

Flotation: Flotation Machines

Dehydration: Thickeners, Filter Presses

The molybdenum ore beneficiation process includes several key stages that ensure efficient mineral recovery and high-grade concentrates. Here’s an overview:

1. Crushing and Screening

Molybdenum ore is first crushed using jaw crushers or double roller crushers to reduce large chunks into smaller, manageable sizes.

Vibrating screens remove oversized particles, ensuring uniform material for grinding.

2. Grinding and Classification

Crushed ore is sent to ball mills for fine grinding, turning it into fine powder.

Spiral classifiers or hydrocyclones then classify the ground material, separating fine particles for the next step.

3. Flotation

Flotation is the core process for molybdenum ore beneficiation. By adding flotation reagents, molybdenum minerals separate from impurities.

Froth containing molybdenum rises to the surface, forming the concentrate, while tailings are discharged.

4. Concentration and Filtration

The flotation concentrate undergoes thickening to remove excess water using a thickener.

Further dehydration is achieved with a filter press, resulting in low-moisture molybdenum concentrate.

5. Drying and Packaging

The filtered concentrate is dried in a rotary dryer.

Finally, the dry molybdenum concentrate is packaged and prepared for shipment or market use.

Recommended Equipment

Crushing: Double Roller Crushers, Jaw Crushers

Grinding: Ball Mills

Classification: Spiral Classifiers, Hydrocyclones

Flotation: Flotation MachinesDehydration: Thickeners, Filter Presses

We recommended a complete crushing solution: jaw crusher, double roller crusher, and vibrating screen. The jaw crusher reduces the 10 cm stones to about 3 cm. Next, the double roller crusher processes the material into 3 mm sand. Finally, the vibrating screen separates the finished product by size.

Our factory has a trial production line with the same configuration. The customer personally tested the crushing effect and saw the equipment’s operation. The rotary drum screen separated the materials into three grades: 3-5 mm, 1-3 mm, and below 1 mm. This allowed him to observe the precise grading of crushed materials.

The following day, we took him to a local production site. This site handled similar raw materials and output sizes as his requirements. He observed the crushing performance and product quality firsthand. By the end of his visit, he was highly satisfied with the equipment and our service.

For pebble sand-making solutions, visit us and test our advanced equipment. We welcome all sand plant owners to explore our reliable crushers.

Applications of Huashengming double roller crusher production line

Huashengming’s range of double roller crusher production line meets the needs of various industries. Whether for large-scale projects or small applications, our machines deliver consistent results.

Limestone

Limestone processing requires the right equipment. Huashengming designs durable and efficient limestone crushers tailored to your specifications.

Gypsum

We offer custom crushers to process both synthetic and natural gypsum rock into the desired product size.

Bauxite and Barite

Our engineers design robust crushers for reducing bauxite and barite into the required dimensions.

Other Materials

Our machines also handle sandstone, gravel, and other industrial materials. We specialize in creating custom solutions for all rock types.

Why Choose Huashengming’s Crushers?

Huashengming Heavy Industry takes pride in offering high-quality machines for crushing stone. No matter the project size, our crushers deliver reliable performance.

Key Features:

- Ability to crush a wide variety of materials.

- Durable construction that lasts for decades.

- Custom designs tailored to your specific needs.

Explore our extensive catalog today and discover why Huashengming Heavy Industry is your trusted partner for stone crushing solutions.

]]>Firstly, the double roller crusher is the core machine, delivering precise crushing for increased production rates. Next, the vibrating screen evenly sorts materials, ensuring uniform particle sizes across different specifications. Then, the sand washer thoroughly cleans the materials, removing impurities for higher quality sand. Finally, the dewatering screen dries the sand, securing optimal end-product quality.

This production line was meticulously designed and assembled to ensure seamless machine cooperation. With such a well-integrated setup, customers can swiftly begin operations and achieve optimal output. This efficient sand production line is not only productive but also easy to maintain, promising high returns on investment.