box hammer crusher

What Exactly Is a Box Hammer Crusher?

Core Advantages of Box Hammer Crushers

1. High Crushing Ratio & Uniform Product Size

2. Compact Structure & Easy Installation

3. Low Operation & Maintenance Costs

4. Strong Adaptability to Raw Materials

Typical Applications of Box Hammer Crushers

-

Quarry Aggregate Production: Used in limestone/dolomite/gypsum quarries to produce aggregates for concrete, mortar, and road bases, meeting quality standards.

-

Construction Waste Recycling: Crushes concrete blocks/bricks into reusable aggregates, promoting waste reuse and reducing pollution.

-

Mining Industry: Primary crushing of ROM materials (coal, iron ore) with adaptability to varying ore hardness.

-

Road & Bridge Construction: Provides efficient aggregate crushing, usable on mobile stations for on-site flexibility.

Key Tips for Selecting a Box Hammer Crusher

-

Material Characteristics: Clarify type, max feed size, and moisture. Choose thicker wear-resistant parts for abrasive materials.

-

Production Requirements: Determine hourly output (50-500 TPH) and desired product size.

-

Site Conditions: Opt for compact models (limited space) or mobile ones (multi-site use).

-

Quality & After-Sales: Choose reputable manufacturers; prioritize after-sales support (wear parts, maintenance, training).

-

Energy Efficiency: Select energy-saving models with optimized rotors.

Final Thoughts

The Current State of the Crushed Stone Market: Challenges Loom Large

Bright Spots Amid the Gloom: Who Is Still Making Money?

Key Factors Determining Profitability: Beyond Market Trends

1. Cost Control: The Lifeline of Profitability

2. Product Differentiation: Escaping Price Wars

3. Policy Compliance: Avoiding Operational Risks

Conclusion: Profitability Is Possible for the Prepared

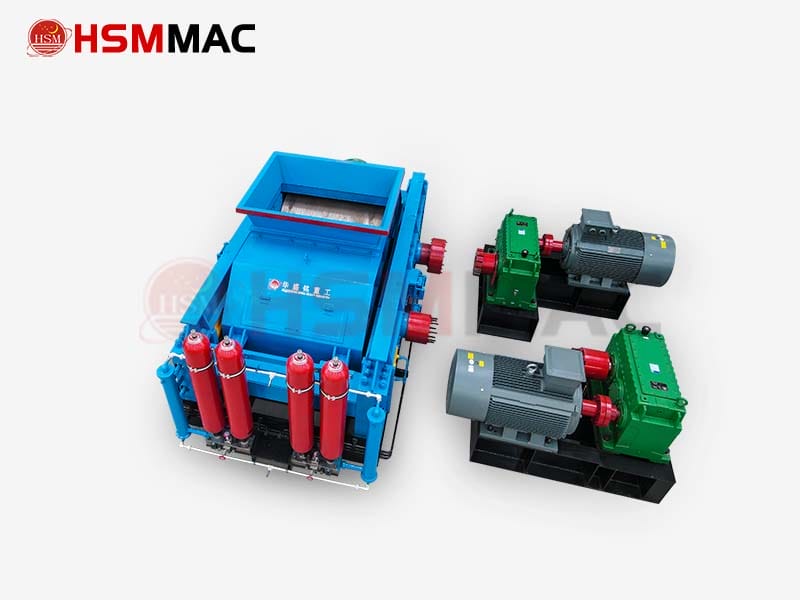

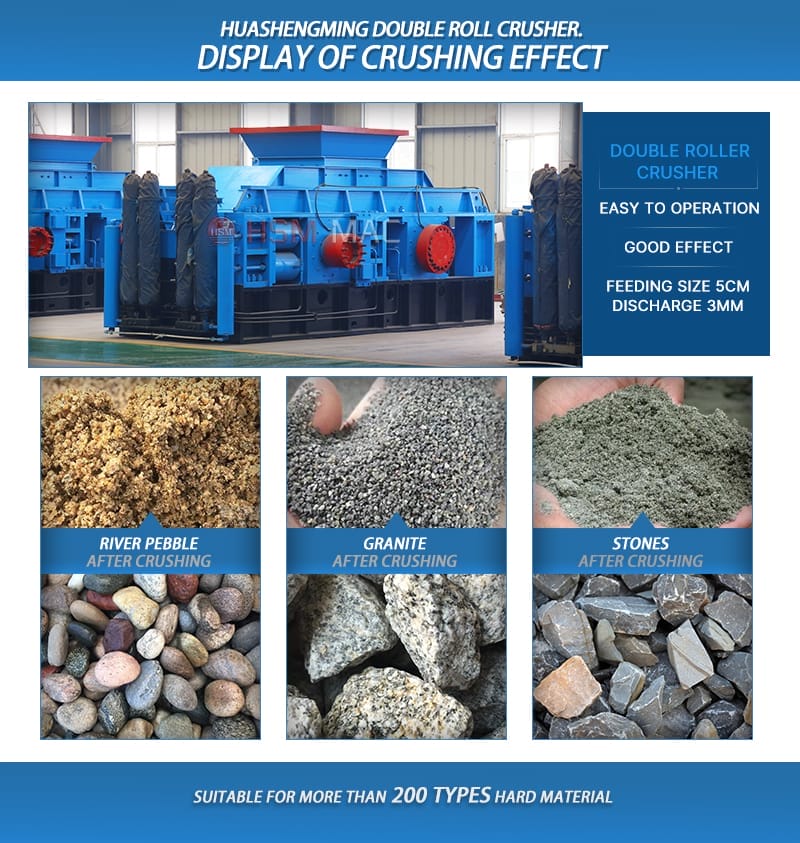

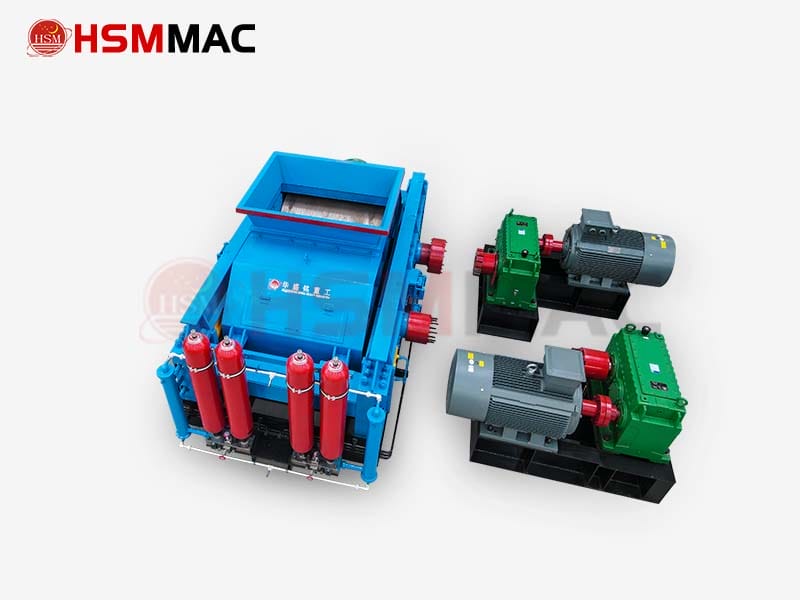

hydralic roller crusher

Advantage 1: Precise Size Control

-

Adjustable roll gap (1-30mm) for precise calibration.

-

Produces uniform output with an ultra-fines generation rate below 8%.

-

Creates ideal feed material for the?Bricks Sand Making Machine.

Advantage 2: Significant Energy Efficiency

Roller Crusher

-

Reduces specific energy consumption by 30-40% compared to impact crushing.

-

Low-speed, high-torque design is well-suited for brick crushing characteristics.

-

Lowers overall system energy consumption, improving economic returns.

Advantage 3: Broad Material Adaptability

-

Capable of processing brick material with clay content up to 15%.

-

Tolerates construction waste with small amounts of wood or plastic.

-

Easy maintenance leads to low operating costs.

Advantage 4: Superior Environmental Performance

-

Enclosed design reduces dust emissions by over 60%.

-

Noise levels controlled below 85dB.

-

Complies with international environmental standards.

Advantage 5: High Return on Investment (ROI)

-

Typical equipment payback period of 8-14 months.

-

Paired with a?Bricks Sand Making Machine, significantly enhances overall system profitability.

-

Durable construction ensures low maintenance costs.

Roller Crusher

1. Gentle Yet Effective Processing

Our Roller Crusher provides the optimal balance between crushing efficiency and material preservation when processing soil. Unlike high-impact crushers that can pulverize clay particles, the controlled compression method maintains soil structure while achieving the necessary size reduction for your?soil sand making machine.

2. Superior Moisture Management

Designed specifically for soil applications, our Roller Crusher handles materials with 15-30% moisture content without clogging. The counter-rotating rolls create a self-cleaning action that prevents material buildup, ensuring continuous operation in your?soil sand making machine?production line.

3. Energy-Efficient Operation

Compared to impact crushers, our Roller Crusher operates at 35% lower power consumption when processing soil materials. The efficient compression technology reduces energy costs while maintaining high throughput for your complete?soil sand making machine?system.

4. Consistent Particle Size Control

The adjustable roll gap allows precise control over final product specifications. This ensures uniform feed for your downstream?soil sand making machine, optimizing its performance and producing consistently graded manufactured sand that meets construction standards.

5. Low Maintenance & High Durability

With fewer moving parts and specially coated rollers resistant to soil abrasion, our Roller Crusher requires minimal maintenance. The robust design withstands the variable characteristics of different soil types, providing reliable operation in your?soil sand making machine?processing plant.

]]>

Smooth Roll Crushers

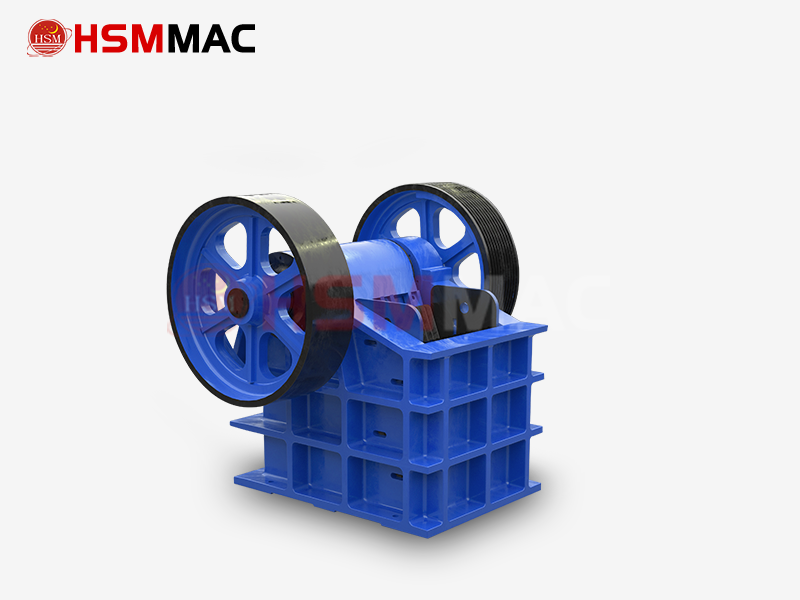

Jaw crusher

1. Superior Durability Against Abrasion

When processing abrasive granite, Huashengming's Jaw Crusher delivers exceptional durability through high-manganese steel jaws and reinforced frame construction, specifically designed to resist wear from granite's high silica content.

2. Consistent High-Volume Production

Our crusher provides reliable, high-volume primary reduction with consistent output size, creating the uniform feed necessary for efficient secondary crushing and optimal operation of your?granite sand making machine.

3. Operational Reliability and Efficiency

The simple, robust design ensures high availability with easier maintenance, minimizing downtime while maximizing overall plant productivity for your complete?granite sand making machine?production line.

]]>

Small Mobile Crusher

Jaw Crusher

Every efficient marble processing operation begins with reliable primary crushing.

Our?Jaw Crusher?serves as the essential first stage in breaking down large marble blocks into manageable sizes.

Jaw Crusher

Designed in our Gongyi factory for durability and performance, it provides the initial size reduction necessary for efficient downstream processing. The jaw crusher's robust construction handles the variable characteristics of marble feed, while its adjustable discharge setting allows for optimal feed preparation for secondary crushers like our?Roller Crusher.

This primary crushing stage sets the foundation for your entire marble processing circuit, ensuring consistent throughput and preparing material for value-added production.

Build your marble processing on a solid foundation. Contact us for jaw crusher solutions tailored to your operation.

hydralic roller crusher

spring roll crusher

Roller Crusher

1.Creates Ideal Sand Maker Feed:

Produces a consistent, cubical feed with minimal oversize and controlled fines, allowing your downstream?dolomite sand making machine?to operate at peak efficiency and produce higher-quality sand.

2.Maximizes Saleable Yield:

Significantly reduces the generation of unmarketable, dusty fines during the crushing stage, increasing the volume of valuable, in-spec sand product.

3.Reduces Total System Wear:

By providing a well-prepared feed, it decreases the abrasive load and impact on the more complex?dolomite sand making machine, lowering its maintenance costs and extending its liner life.

4.Offers Precise Size Control:

The adjustable roll gap allows you to fine-tune the feed size for your specific sand maker model and target sand gradation, providing unparalleled process flexibility.

5.Enhances Overall Energy Efficiency:

A more efficient crushing stage with a roller crusher reduces the overall power consumption of your complete sand manufacturing plant.

Unlock these benefits in your sand plant. Request detailed technical specifications for our dolomite-optimized Roller Crusher today.

]]>