Box Hammer Crusher

Impact Crusher

Core Traits & Adaptation

Quick Selection Tip

]]>

Four roller crusher

1. Targeted Wear Resistance for High-Hardness Blue Quartz

2. Superior Particle Quality with “Extrusion + Shear” Technology

3. Flexible Adaptability for Diverse Needs

4. Certified Reliability for Global Projects

]]>

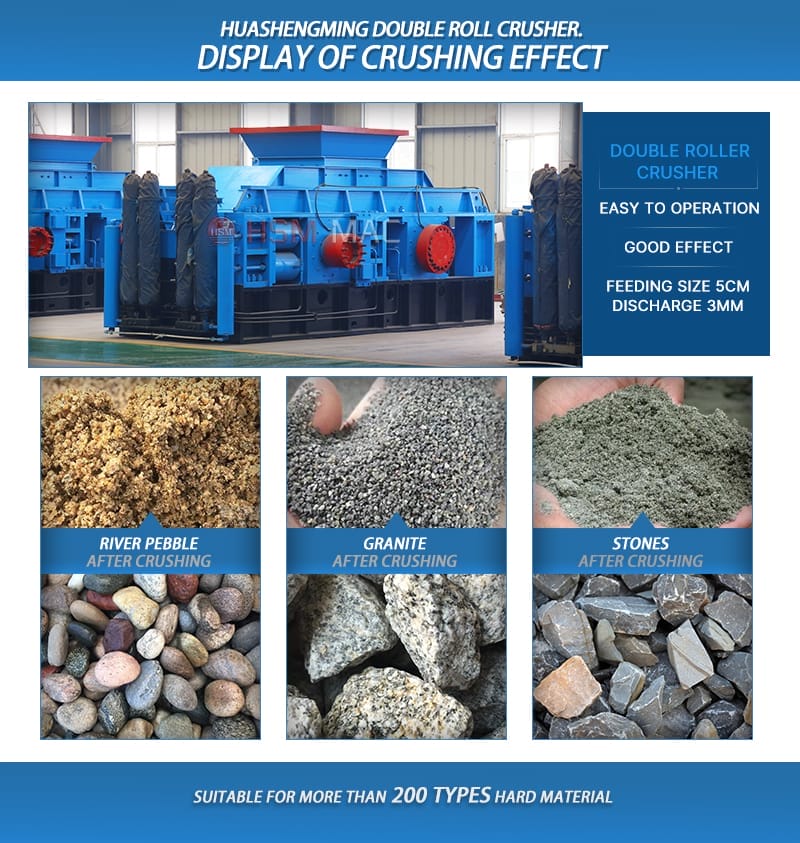

Roller Crusher

Core Advantages

1. Energy-Saving Operation

2. Precise Sizing & High-Quality Output

3. Wide Material Adaptability

Seamless Line Integration

]]>—— Turn High-Hardness Basalt into High-Quality Construction Sand

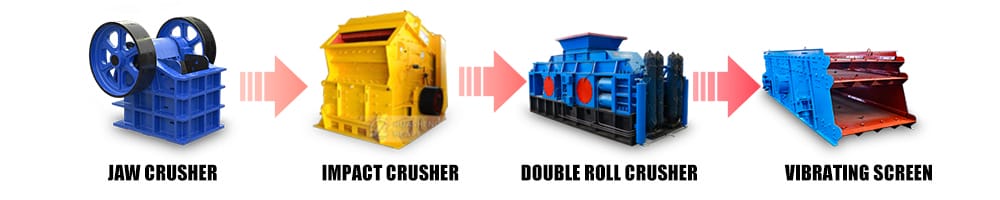

I. Core Production Line Process

? ?2.Crushing & Shaping

The basalt sand making machine uses double-roller extrusion to crush and shape basalt. The result: 90%+ cubic particles, ≤5% powder — no over-crushing (a flaw in traditional methods).

3.Classification & Screening

Send crushed material to a vibrating screen. Sort into 3 sand grades: coarse (5-10mm), medium (2-5mm), fine (0-2mm). Send unqualified large particles back to the machine for re-crushing (100% pass rate).

4.Finished Product Storage

Move qualified sand to a silo via conveyor, or load directly for transport. Use it for construction, roads, etc.

]]>

Key Advantages of Spring Roll Crushers

As specialized equipment for spring rolls and similar wrapped delicacies, the spring roll crusher inherits double-roll structural merits with food-processing optimizations, standing out in efficiency, usability, and product quality.

spring roll crusher

1. High Raw Material Utilization (Up to 98%)

2. Effortless Texture Adjustment

3. High Product Purity & Hygiene Compliance

4. Compact & Energy-Efficient

Crushing Principle of Roller Crusher

1. Hardness-Adapted Design: No Fear of Tough Materials

2. Durable & Low-Maintenance: Cut Replacement Costs

Roller Skin

3. High-Quality Finished Products: Ready for Use

4. Energy-Saving & Eco-Friendly: Cost-Effective and Compliant

]]>

1. Working Principle

The operation of a double-roll crusher is highly intuitive: two rolls rotate toward each other driven by an electric motor. Material enters the crushing chamber formed between the rolls from the top, where it undergoes continuous compression and shearing forces to achieve the desired particle size. By adjusting the gap between the rolls (roll clearance), the maximum particle size of the product can be precisely controlled.

2.Advantages

Superior particle size control: This is its core advantage. Slow compression and shearing action ensures uniform material fragmentation while significantly reducing the production of excessively fine powder. This is crucial for industries requiring consistent finished particle size, such as high-quality concrete aggregates.

Energy-Efficient Operation: Typically consumes lower energy when crushing materials below medium hardness. Integrating a double-roll crusher for pre-crushing in grinding systems can substantially boost overall system throughput.

Simple Structure and Easy Maintenance: Features relatively uncomplicated mechanical design with low failure rates. Routine maintenance and replacement of wear parts (e.g., roll liners) are straightforward, contributing to reduced long-term operational costs.

Sensitive overload protection: Equipment is typically fitted with spring or hydraulic relief devices. When non-crushable foreign objects (e.g., iron pieces) enter the crushing chamber, the rollers automatically retract to discharge the obstruction, effectively safeguarding core machine components from damage.

Mine Dumping Rocks Crusher

Summary

Overall, the double-roll crusher is a highly effective piece of equipment in specific applications. If your mine primarily produces medium-to-low hardness brittle materials such as coal or limestone, and you have stringent requirements for uniform final particle size, powder content, energy consumption, and operational costs, then the double-roll crusher is undoubtedly an efficient, economical, and environmentally friendly choice.

]]>1. Small Stone Crusher Machine

Feed Size: 25-100mm

Production Capacity: 2-400 t/h

Suitable Materials:

River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc.

Application Scope:

Suitable for crushing in mining, cement, highway, railway, coal, metallurgy, building materials, and other industries.

2.Working Principle

2.Working Principle

performs crushing operations via roller wheels. Material enters between the rollers through the feed opening and is crushed by compression. A fixed gap exists between the two rollers. Increasing this gap produces larger output particle sizes, while the compression spring reduces the gap to produce finer output. Adjusting the gap allows precise control over the final particle size.

3.Performance Advantages

1. Simple and lightweight with powerful crushing force

2. High efficiency, low energy consumption, and superior output quality

3. Wide applicability and extended service life

4. Intelligent control for energy savings and labor reduction