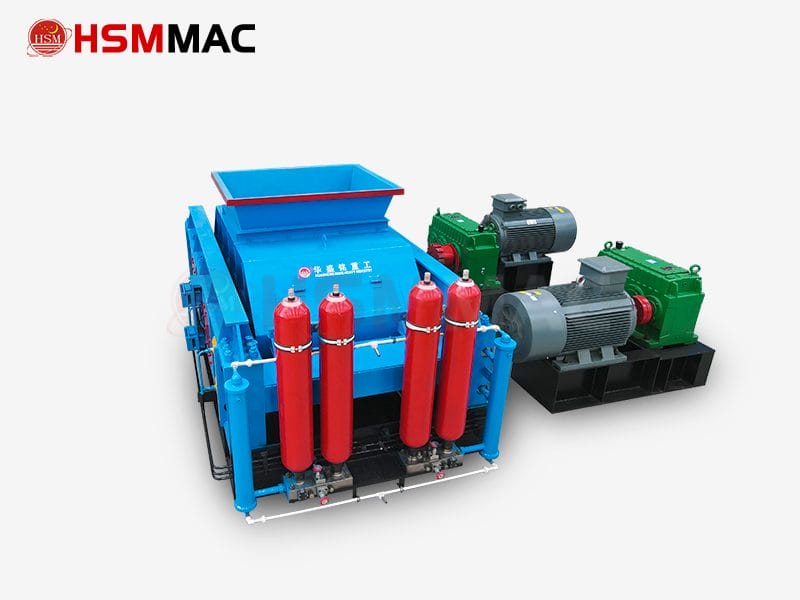

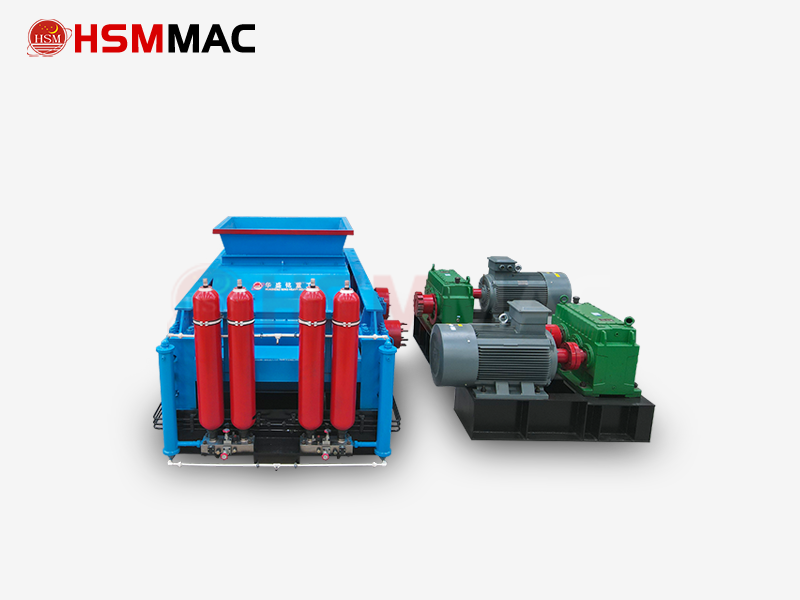

Double roll crusher factory direct sale

2025-07-31

Huashengming roll crusher has excellent production capacity. Through the rotating and squeezing action of the rollers, the machine is able to quickly crush the raw materials into the required particle size, which greatly improves the production efficiency of sand and gravel. This efficiency not only helps the sand and gravel plant to meet the demand for large-scale production, but also saves time and labour costs significantly. Huashengming HeavyIndustry was established more than several years, has more rich practical experience, and the quality of the equipment produced, after-sales service is very good, and the price of its equipment is also very favourable. Huashengming Heavy Industry has a large-scale production plant, standardised testing facilities, and now has a number of branch factories, and it occupies a very important position in the market. Gongyi City Huashengming Heavy Industry Machinery Factory is a large-scale machinery intellectual enterprise mainly producing crushing and screening equipment, integrating production and sales. The main business includes crushing, sand making, grinding, building materials, mineral processing equipment production and sales, and actively launch a variety of new equipment, while providing one-to-one service, refinement to meet user needs. After years of development, the market share is increasing, while actively developing foreign markets,…