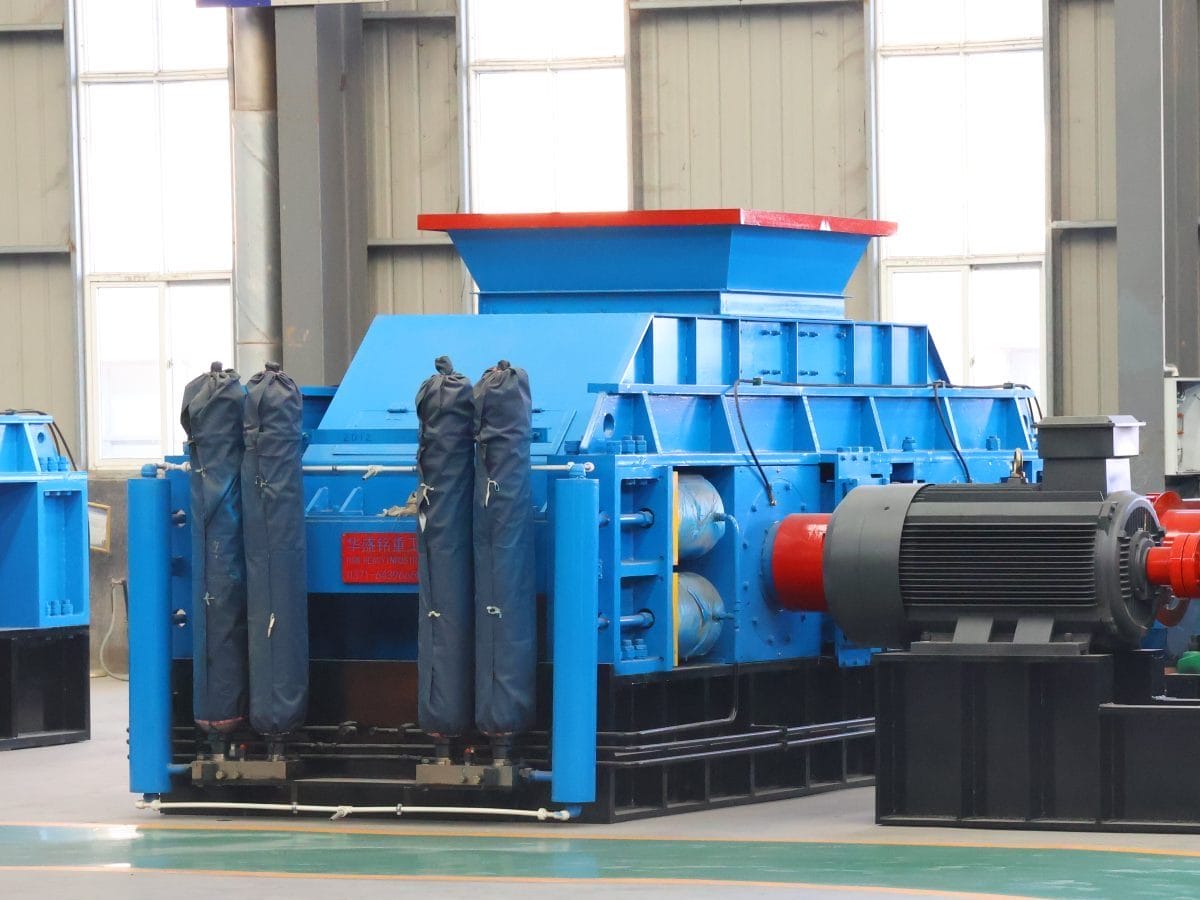

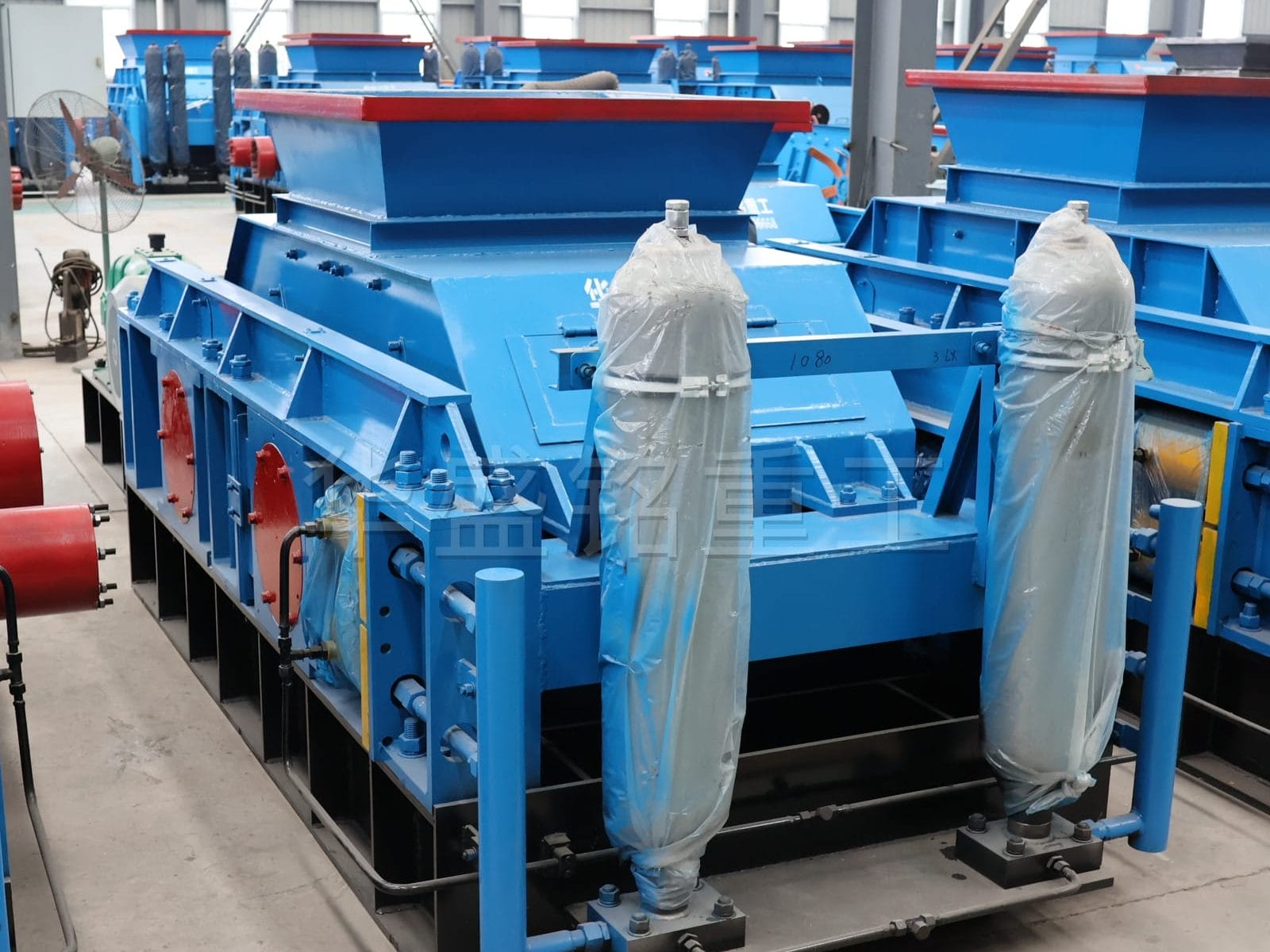

A Double-Roll Sand-Making Machine Capable Of Producing Output Sizes Of 1-3 Millimeters

2025-10-24

The double-roll sand-making machine is an upgraded version of the conventional spring-loaded double-roll crusher, utilizing hydraulic cylinders for pressure output. Older spring-loaded models require manual spring pressure adjustment after prolonged use to meet finished product specifications, whereas the Dou Shi hydraulic double-roll sand-making machine features automatic pressure regulation with precise compensation. Suitable for fine crushing operations with feed sizes under 80mm and finished product sizes ranging from 50μm to 20mm. It offers more convenient, efficient, and flexible operation, produces uniformly sized particles, minimizes on-site dust pollution, delivers excellent performance, requires minimal floor space, allows easy adjustment of the crushing ratio, and operates reliably. 1.Double-roll Sand Making Machine Feed Size: 25-100mm Production Capacity: 2-400 t/h Suitable Materials: Highways, high-speed railways, high-rise buildings, municipal projects, hydroelectric dam construction, concrete mixing plants, sand and gravel yards, etc. Application Scope: Suitable for coal, metallurgy, mining, chemical, and building materials industries. Particularly suitable for crushing raw coal (including gangue) in large coal mines or coal preparation plants. 2.Applicable Materials Suitable for crushing and sand-making operations involving materials such as river pebbles, calcite, quartz, glass, marble, cobblestones, bentonite, iron ore, bluestone, mountain rock, limestone, weathered sand, diabase, granite, and basalt. 3.Working Principle The double-roll sand-making machine…