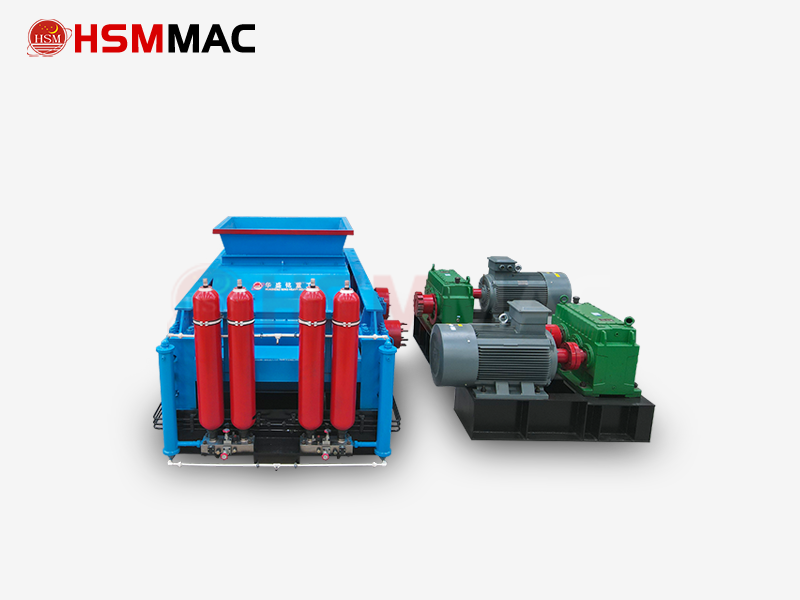

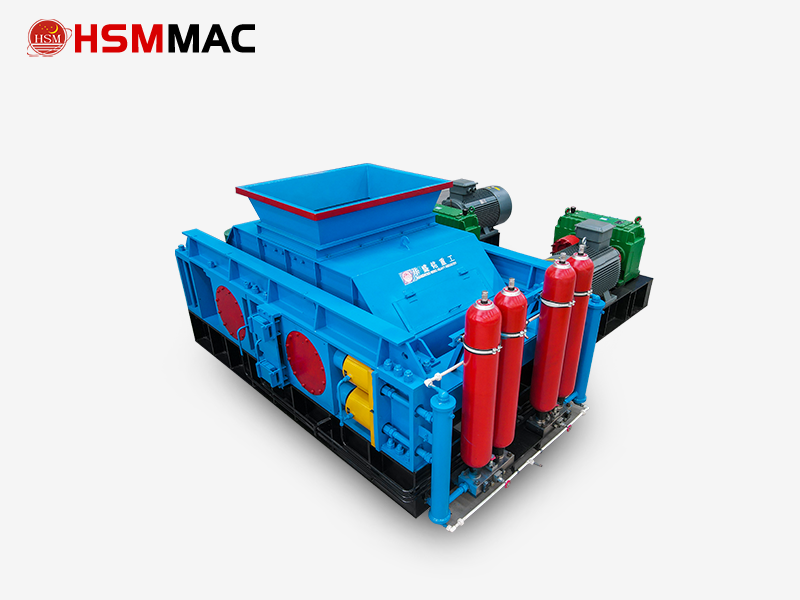

Lump Crusher: Selected Roller Crusher

2025-10-04

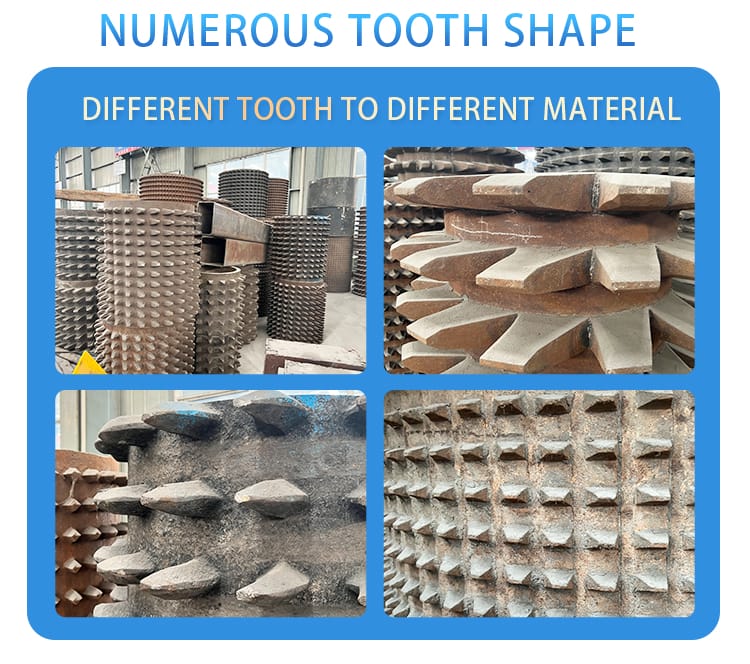

Huashengming Lump Crusher centers on three core series—twin-tooth roller, counter-roller, and box-type heavy hammer—delivering efficient crushing solutions for lump materials (such as ore, coal, construction waste) with varying hardness, moisture content, and particle size requirements. Below is a detailed analysis of its core technologies, product series, and application scenarios: 1. Core Product Series and Technical Features Twin-Tooth Roller Crusher Working Principle: Applies squeezing + shearing forces to materials via two counter-rotating toothed rollers, achieving flexible crushing that reduces over-crushing and increases block retention rate by over 30%. Particle Size Control: Adjustable roller gap (1-50mm) enables precise output size control (e.g., coal crushing to 20-40mm), meeting diverse industry requirements. Wear-Resistant Design: Roll teeth feature a high-chromium alloy + rare metal composite material (triple-layer composite structure), delivering over twice the service life of conventional equipment (handling capacity exceeding 30,000 tons). Applications: High-moisture, sticky materials like coal, coke, limestone, and clay-bearing gold ore (moisture content ≤15%). Double Roll Crusher Hydraulic/Spring Adjustment: Supports stepless roll gap adjustment (±0.1mm precision), output particle size range 1-40mm, over-crushing rate below 10%. Power Adaptability: Supports electric, diesel dual power, or PTO drive (connects to tractors), suitable for off-grid mining areas. Model Coverage: Small Unit (250×400): 2-10 tons/hour Large…